- Get link

- X

- Other Apps

Use CO 2 and sunlight as substrate which are without any cost. SCP from algae has about 60 crude protein which is generally good in amino-acid composition except for some deficiency in Sulphur containing amino-acids.

Different Metabolic Routes Available To Algae Under Various Download Scientific Diagram

Different Metabolic Routes Available To Algae Under Various Download Scientific Diagram

Based on Application the market is bifurcated into Marine Sector Aviation Sector Road Transport DHA Production Protein Sales DHA Production Pharmaceutical Applications Bioplastics and Others.

Algae protein production. Production technology must be. So far however research on algal bioreactors for recombinant protein expression is very rare calling for further investigations in this highly promising field. Increasing consumption of protein products across the world owing to changing lifestyles and rising health consciousness among consumers has been driving the market in recent years.

Soluble protein can then easily be separated from carbohydrates by acidic precipitation at low pH. However standard procedures to reliably quantify these components are not readily available. Algae proteins also known as algal proteins are extracted from algae particularly from blue-green and green algae since it consists of high protein levels varying from 40 to 60.

Algae is rich in fiber particularly macroalgae which are used to prepare food. In addition microalgae can be grown in containment in enclosed bioreactors Pulz 2001 thus reducing the. Algae proteins constitute high protein content amino acid profile and excellent nutritional capabilities which spur their application in functional processed foods and health foods.

Protein production in transgenic algae could presumably offer many of the same advantages as transgenic plants including cost safety and rapid scalabili-ty. The first significant therapeutic protein produced in algae was a human single-chain antibody Mayfield et al 2003. According to research by Stephen Bleakley and Maria Hayes seaweed at 25-75 tonnes per hectare per year and microalgae at 4-15 tonnes per hectare per year have higher protein yield per unit area than conventional crops such as soybean pulse legumes and wheat.

This review details the characteristics of commonly consumed algae as well as their potential for use as a protein source based on their protein quality amino acid composition and digestibility. Algae use for protein production has several benefits over traditional high-protein crop use in terms of productivity and nutritional value. Classical methods use dissolution of the algae under reductive conditions in alkali.

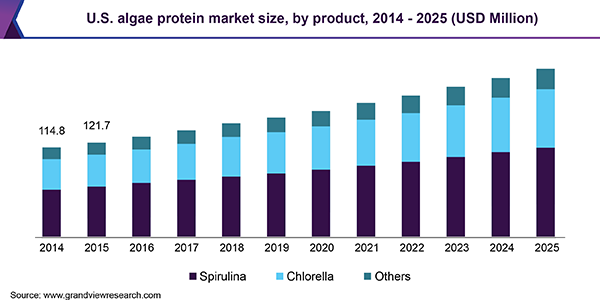

The global algae protein market size was estimated at USD 6908 million in 2018 and is expected to expand at a CAGR of 66 during the forecast period. Although algal proteins can be cultivated and produced in industrial quantities bulk production of microalgal products still awaits a breakthrough in the design of photobioreactors in which high photosynthetic efficiencies are maintained on large scales and at high light intensities during long term operation. Protein extraction methods applied to algae to date including enzymatic hydrolysis physical processes and chemical extraction and novel methods such as ultrasound-assisted extraction pulsed electric field and microwave-assisted extraction are discussed.

Moreover microalgae exhibit a phototrophic lifestyle like land plants hence protein expression is fuelled by photosynthesis which is CO2-neutral and involves only low production costs. It is critical to understand algaes biomass characteristics at various times in the growth cycle to develop cultivation management strategies downstream processes and final products. Further development of production processes of algae proteins.

Increasing concern and awareness regarding healthy and nutritious food products have led to the demand for algae protein across the globe. Members of the genera Chlorella Scendesma Spirullina are generally grown in ponds on tanks. Microalgae come in a diverse range of nutritional profiles and advanced cultivation strategies can be developed for tuning microalgae to produce protein- oil- and carbohydrate-dominant types that can be processed into a broad range of functional foods including healthy cell patties chips pastes jams and even caviar.

Form for recombinant protein production has been gaining in recent years. Seaweed and microalgae have higher protein yield per unit area 2575 tonsHayear and. Microalgae come in a diverse range of nutritional profiles and advanced cultivation strategies can be developed for tuning microalgae to produce protein- oil-.

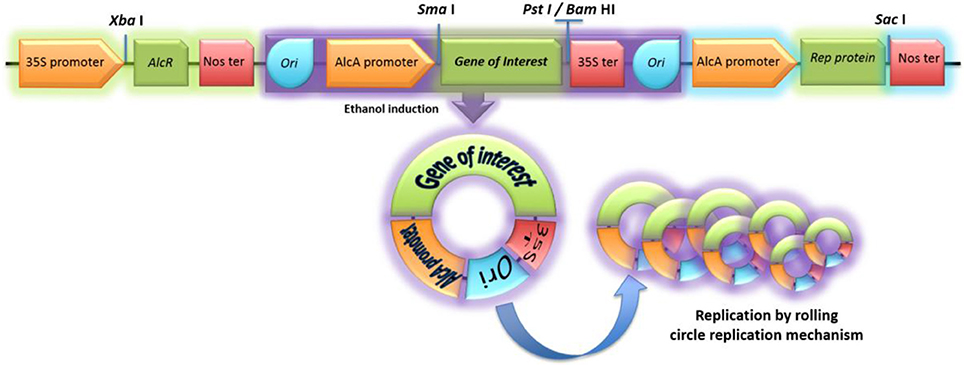

Micro-algae come of age as a platform for recombinant protein production A complete set of genetic tools is still being developed for the micro-alga Chlamydomonas reinhardtii. Fundamental components of algaelike lipids starches and proteinsvary greatly among strains and in comparison to plants. Yet even with this incomplete set this photosynthetic single-celled plant has demonstrated significant promise as a platform for recombinant protein expression.

Most of these have been produced in the chloroplast of Chlamydomonas reinhardtii but there have been several recombinantproteinsproducedinothermicroalgaespecies. More recently a full-length human monoclonal antibody. Algal proteins can be extracted from algae in a simple way and with reasonably high yields using classical solvent andor enzymatic methods.

Protein extraction methods applied to algae to date including enzymatic hydrolysis physical processes and chemical extraction and novel methods such as ultrasound-assisted extraction pulsed electric field and microwave-assisted extraction are discussed.

Frontiers Algevir An Expression System For Microalgae Based On Viral Vectors Microbiology

Frontiers Algevir An Expression System For Microalgae Based On Viral Vectors Microbiology

Towards Protein Production And Application By Using Chlorella Species As Circular Economy Sciencedirect

Towards Protein Production And Application By Using Chlorella Species As Circular Economy Sciencedirect

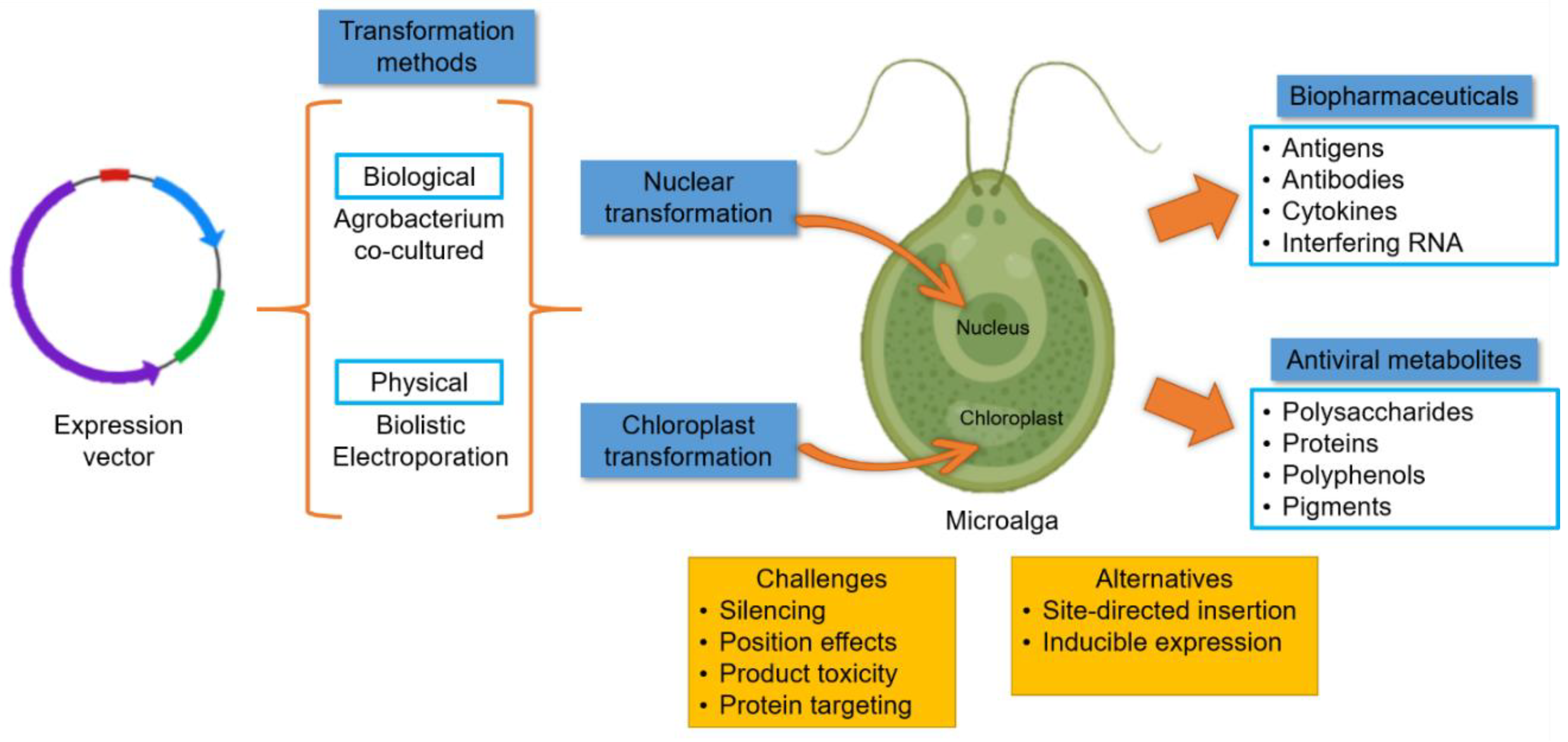

Molecules Free Full Text The Potential Of Algal Biotechnology To Produce Antiviral Compounds And Biopharmaceuticals Html

Molecules Free Full Text The Potential Of Algal Biotechnology To Produce Antiviral Compounds And Biopharmaceuticals Html

Pdf Microalgae As Platforms For Production Of Recombinant Proteins And Valuable Compounds Progress And Prospects

Pdf Microalgae As Platforms For Production Of Recombinant Proteins And Valuable Compounds Progress And Prospects

Microalgae For Integrated Food And Fuel Production Rosch 2019 Gcb Bioenergy Wiley Online Library

Microalgae For Integrated Food And Fuel Production Rosch 2019 Gcb Bioenergy Wiley Online Library

Algae Protein Market Size Share Global Industry Report 2014 2025

Algae Protein Market Size Share Global Industry Report 2014 2025

Extraction And Fractionation Of Microalgae Based Protein Products Sciencedirect

Extraction And Fractionation Of Microalgae Based Protein Products Sciencedirect

Microalgae Protein Grown In Tanks To Be The Next Generation Future Of Food

Microalgae Protein Grown In Tanks To Be The Next Generation Future Of Food

Development Of Protein Isolation Methods From Microalgae Wur

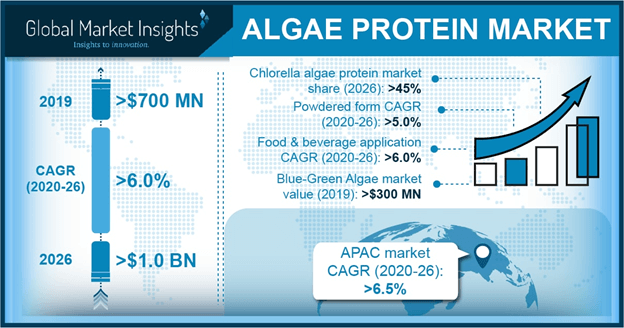

Algae Protein Market Report 2020 2026 Growth Forecasts

Algae Protein Market Report 2020 2026 Growth Forecasts

Foods Free Full Text Algal Proteins Extraction Application And Challenges Concerning Production Html

Foods Free Full Text Algal Proteins Extraction Application And Challenges Concerning Production Html

Microalgae Protein Grown In Tanks To Be The Next Generation Future Of Food

Microalgae Protein Grown In Tanks To Be The Next Generation Future Of Food

We Want To Lower Production Costs And Prove Algae Are Beneficial For Livestock Says Dutch Team

We Want To Lower Production Costs And Prove Algae Are Beneficial For Livestock Says Dutch Team

Figure 1 From Photosynthetic Biomanufacturing In Green Algae Production Of Recombinant Proteins For Industrial Nutritional And Medical Uses Semantic Scholar

Figure 1 From Photosynthetic Biomanufacturing In Green Algae Production Of Recombinant Proteins For Industrial Nutritional And Medical Uses Semantic Scholar

Comments

Post a Comment